Hot-rolled stainless steel coils have a series of remarkable performance characteristics, which make them widely used in many industries. The main performance characteristics are as follows:

1. Corrosion resistance: Hot-rolled stainless steel coils have excellent corrosion resistance due to their alloy composition, especially in corrosive environments such as chemicals and seawater. Austenitic stainless steel is particularly resistant to oxidation and corrosion.

2. High temperature resistance: Stainless steel has good high temperature resistance and can maintain good structural stability in high temperature environments up to 650°C. Some models, such as 316 stainless steel, can withstand higher temperatures without deformation or damage, and are suitable for high temperature operating conditions.

3. Mechanical properties: Strength and hardness: Hot-rolled stainless steel has high strength and hardness, especially the martensitic stainless steel series, which has high hardness and wear resistance.

Ductility and toughness: Austenitic stainless steel has good ductility and toughness, and is suitable for deep processing, forming and welding.

4. Processability: Hot-rolled stainless steel has good processability and can be welded, cut, cold bent and other processing. Austenitic stainless steel is particularly easy to weld and is suitable for the production and processing of complex shapes.

Ferritic and martensitic stainless steels have slightly poorer processability, especially when welding, cracks or other defects may occur.

5. Wear resistance: Due to its high hardness, martensitic stainless steel has good wear resistance and is suitable for applications that require high wear resistance, such as mechanical parts, tools, etc.

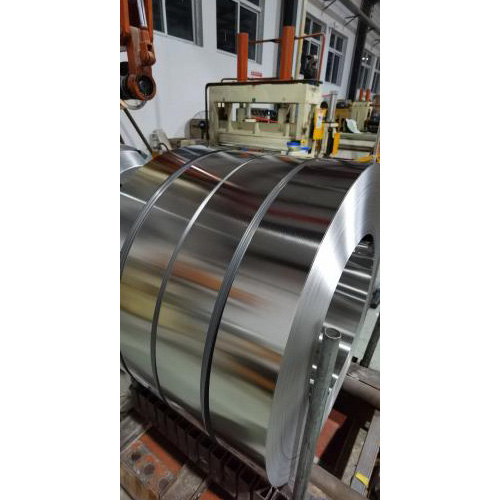

6. Appearance and gloss: The surface of hot-rolled stainless steel coils is usually smooth and has a certain gloss. Especially in applications that require beautiful appearance, such as architectural decoration and home appliance housings, hot-rolled stainless steel has been widely used due to its excellent appearance appeal.

7. Impact resistance: Due to its good toughness, hot-rolled stainless steel performs better when subjected to impact and can withstand large mechanical impacts without cracking or breakage.

8. Low temperature resistance: Hot-rolled stainless steel, especially austenitic stainless steel, has good low temperature performance and can maintain excellent toughness and strength in low temperature environments, making it suitable for freezing and low-temperature storage equipment.

9. Antioxidation: High content of chromium and nickel makes hot-rolled stainless steel effectively resistant to oxidation, especially in high temperature, acidic or alkaline environment, its surface can form a stable oxide film to prevent further oxidation.

10. Environmental protection and hygiene: Because it is smooth and not easy to accumulate dirt, hot-rolled stainless steel is particularly suitable for food processing, medical equipment and other fields. It meets hygiene standards, is easy to clean, and is not easy to breed bacteria.

In summary, hot-rolled stainless steel coils are widely used in chemical, construction, home appliances, automobile and other industries due to their excellent corrosion resistance, high temperature resistance, processability and aesthetics, and are also used in some high-strength and wear-resistant occasions due to their strength, wear resistance and impact resistance.