The Ultimate Guide to Choosing the Right Stainless Steel Supplier for Your Projects

Selecting the right stainless steel supplier is critical for the success of your projects, particularly in industries such as construction, manufacturing, and automotive, where the demand for high-quality materials is paramount. According to a report by Smithers Pira, the global stainless steel market is projected to reach 50 million tonnes by 2025, underscoring the increasing reliance on stainless steel across various applications. As companies seek reliable and durable materials, partnering with a reputable stainless steel supplier becomes essential. Not only do reputable suppliers provide consistent product quality and compliance with industry standards, but they also offer valuable expertise and support. Ensuring that your supplier is equipped to meet both your immediate and long-term project needs can significantly influence both the efficiency and outcome of your work.

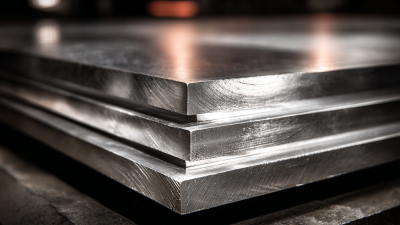

Understanding Different Types of Stainless Steel and Their Applications

When selecting the right stainless steel for your projects, understanding the different types and their specific applications is crucial. Stainless steel is divided into several categories, including austenitic, ferritic, martensitic, duplex, and precipitation-hardening stainless steels. According to a report by Grand View Research, the austenitic stainless steel segment alone accounted for over 70% of the global market in 2021, highlighting its popularity due to excellent corrosion resistance and versatility in various environments.

Austenitic stainless steels, notably grades 304 and 316, are commonly used in food processing, chemical production, and biotechnology due to their high resistance to oxidation and acids. Ferritic and martensitic types, while offering adequate strength and resistance, are typically employed in less corrosive environments, such as automotive parts or kitchen utensils. Recent industry studies indicate that the demand for duplex stainless steels, known for their improved strength and corrosion resistance, is projected to grow significantly, driven by industries such as oil and gas. Understanding these distinctions allows businesses to select the most appropriate stainless steel type, ensuring durability and efficiency in their projects.

The Ultimate Guide to Choosing the Right Stainless Steel Supplier for Your Projects

Key Qualities to Look for in a Stainless Steel Supplier

When selecting a stainless steel supplier for your projects, certain key qualities can significantly impact the effectiveness and efficiency of your procurement process. First, consider the supplier's industry experience and reputation. A supplier with a long-standing history in the stainless steel market is likely to have established robust relationships with manufacturers and possess comprehensive product knowledge. This experience generally translates into better quality materials, reliable service, and expert guidance on materials selection.

Another critical quality to look for is the supplier's ability to provide customized solutions. Each project may have unique requirements, and a supplier who can tailor their offerings—such as specific grades, shapes, or finishes of stainless steel—can add considerable value. Additionally, strong customer service and support are essential. A responsive supplier who communicates effectively can help navigate challenges that arise during the project, ensuring a smoother workflow and timely delivery to meet project deadlines.

Prioritizing these qualities will help secure a dependable partner for your stainless steel needs.

Evaluating Supplier Certifications and Industry Standards

When selecting a stainless steel supplier, understanding their certifications and adherence to industry standards is crucial. Certifications such as ISO 9001 indicate a commitment to quality management systems, ensuring your projects meet rigorous requirements. Additionally, suppliers that comply with ASTM standards demonstrate that their products are tested for performance and safety, which is essential for both durability and compliance in various applications.

**Tips:** Always request documentation for certifications directly from potential suppliers. This transparency will help you ascertain their credibility and commitment to quality. Be on the lookout for industry-specific certifications that may apply to your project, as these can provide further assurance of a supplier's expertise and reliability.

Moreover, engaging with suppliers that are recognized by industry associations can enhance your confidence in their offerings. Membership in organizations like the American Iron and Steel Institute (AISI) indicates a supplier's dedication to high standards and best practices.

**Tips:** Utilize online resources to research suppliers' reputational standing within these associations. Evaluating customer reviews and case studies can provide valuable insights into a supplier's performance and reliability over time.

Assessing Pricing Models and Delivery Options for Stainless Steel

When selecting a stainless steel supplier, one critical aspect to consider is the pricing model they offer. Various suppliers may adopt different strategies such as fixed pricing, tiered pricing based on volume, or fluctuating prices influenced by market conditions. Understanding these pricing models is essential, as it directly impacts your project's budget. Engaging in discussions with potential suppliers about their pricing structure allows you to compare and assess how it aligns with your purchasing strategy. Negotiating discounts for bulk orders or long-term contracts can also lead to significant savings.

Delivery options are equally important when choosing a stainless steel supplier. Timely delivery is crucial for maintaining project schedules, so it’s vital to evaluate the supplier's logistics capabilities. Some suppliers may offer expedited shipping, while others may have a standard lead time that could affect your operational timeline. Furthermore, the geographic location of the supplier can influence delivery times and costs. It is advisable to inquire about their inventory management practices and soil ensure that they can meet your project demands promptly, thus minimizing any potential delays in your workflow.

Customer Support and Communication: A Crucial Factor in Supplier Selection

When selecting a stainless steel supplier, customer support and communication stand out as pivotal factors that can significantly influence project outcomes. According to a 2022 report by the Stainless Steel Industry Association, over 70% of companies consider effective communication and customer service as primary criteria when choosing a supplier. This is not merely a matter of preference; clear communication can prevent costly errors during production and ensure that materials meet specific project requirements.

A supplier that prioritizes customer support typically provides timely updates on order status, addresses concerns promptly, and offers technical assistance when needed. With industry data indicating that responsive suppliers can reduce lead times by up to 30%, it is evident that solid customer support translates into better project efficiency. Furthermore, a survey from Market Research Future reveals that 68% of project delays are linked to inadequate communication with suppliers, highlighting the necessity for ongoing dialogue throughout the supply chain.

Therefore, when evaluating potential stainless steel suppliers, consider their commitment to customer support and the quality of their communication systems—these factors are likely to determine not just satisfaction, but the overall success of your projects.

Related Posts

-

Innovative Trends and Market Insights for Welded Wire Mesh at the 2025 China Import and Export Fair

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

Mastering Stainless Steel Welding Techniques for Superior Joints and Durability

-

Revitalize Your Cleaning Routine: Discover the Power of Steel Brushes for Every Task

-

Discovering the Versatility and Durability of 304 Stainless Steel in Modern Applications

-

Exploring Opportunities for Metal Mesh Innovations at the 138th China Import and Export Fair 2025