Everything You Need to Know About Small Wire Brushes for Cleaning

When it comes to cleaning tasks, a small wire brush can be a valuable tool. According to industry expert John M. Taylor, "A small wire brush can reach tight spaces and provide an effective clean." This highlights its importance in various applications. Whether you're maintaining machinery or restoring surfaces, its utility cannot be overstated.

Using a small wire brush requires careful consideration. The bristles can be abrasive, potentially damaging delicate surfaces if used improperly. It's vital to choose the right brush for the job. A brush that is too stiff may scratch, while one that is too soft might not clean effectively. Finding the balance is key to achieving the desired results while preserving the integrity of the materials.

Moreover, while the small wire brush is versatile, it has its limitations. It may not be suitable for every cleaning scenario. Users should be aware of effective techniques that maximize its benefits. Like any tool, practice and reflection on its use can lead to improved results. Embracing its potential while acknowledging its drawbacks is crucial for successful cleaning endeavors.

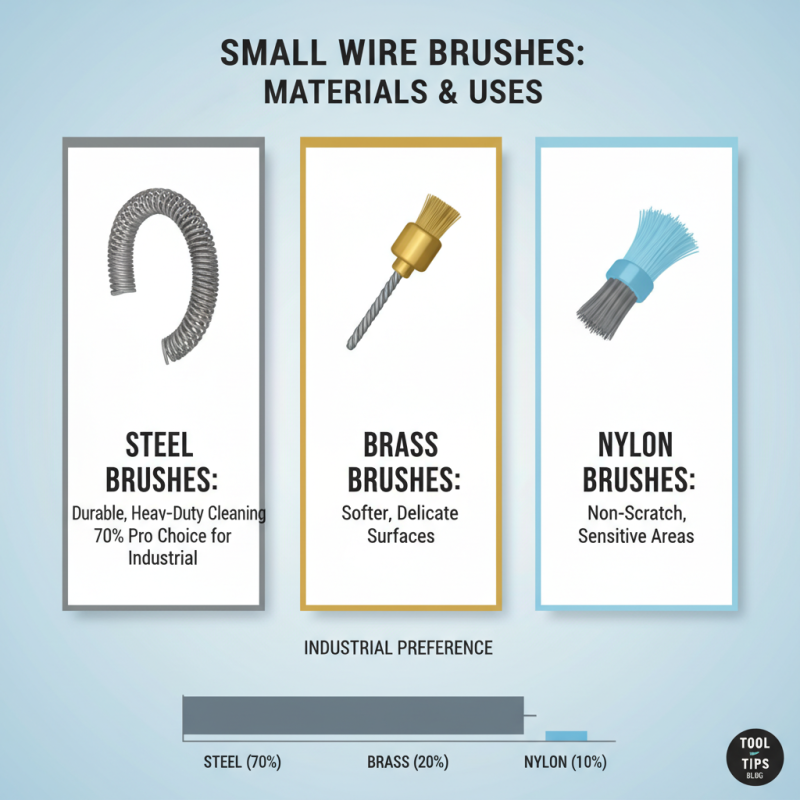

Types of Small Wire Brushes: Materials and Design Variations

When it comes to small wire brushes, the choice of materials and design variations can significantly impact their effectiveness. Wire brushes are commonly made from materials like steel, brass, and nylon. Steel brushes are durable and excellent for heavy-duty applications. Brass brushes are softer and ideal for delicate surfaces. Nylon brushes offer a non-scratch option, making them suitable for cleaning sensitive areas. According to industry reports, about 70% of professionals prefer steel brushes for industrial cleaning tasks.

Design variations also play a crucial role. Small wire brushes are available in different shapes, including flat, round, and angled heads. Each shape serves a specific purpose. For instance, angled brushes can navigate tight spaces that flat brushes cannot. The handle's design is equally important; ergonomic handles reduce fatigue, especially during prolonged use. Reports indicate that ergonomic designs enhance user performance by nearly 30%.

However, it's worth noting that not all brushes perform as expected. Users sometimes overlook the importance of selecting the right type for their specific tasks. A heavy-duty steel brush may damage softer materials, showcasing the need for careful consideration. A mismatched brush can lead to inefficiency and poor results.

Key Applications of Small Wire Brushes in Various Industries

Small wire brushes play an essential role in various industries. They are commonly used for cleaning surfaces and preparing materials. In the automotive sector, for instance, wire brushes are critical in removing rust and corrosion from metal parts. A study indicates that rust can reduce the lifespan of automotive components by up to 30%. Regular cleaning with wire brushes can enhance durability.

In the manufacturing realm, small wire brushes are vital for surface finishing. They help achieve smooth surfaces, especially in metal fabrication. According to industry reports, over 50% of manufacturers utilize wire brushes daily. However, improper use can lead to surface damage. Users often overlook the right technique, which can compromise the integrity of the material.

Furthermore, wire brushes serve a key role in maintenance and repair. In the HVAC industry, they are used to clean coils and ducts. Studies show that uncleaned systems can reduce efficiency by nearly 25%. Yet, many technicians skip this step, impacting system performance. Careful application is essential, highlighting the need for training in using these tools effectively.

Everything You Need to Know About Small Wire Brushes for Cleaning

| Industry | Key Application | Brush Material | Common Uses |

|---|---|---|---|

| Automotive | Engine Parts Cleaning | Steel Wire | Removing grease and grime from components. |

| Aerospace | Surface Preparation | Brass Wire | Cleaning parts before coating or painting. |

| Manufacturing | Deburring | Stainless Steel Wire | Removing sharp edges from machined parts. |

| Construction | Rust Removal | Nickel-plated Wire | Preparing metal surfaces for painting. |

| Electronics | Circuit Board Cleaning | Bronze Wire | Removing flux and residues. |

Effectiveness of Small Wire Brushes for Removing Rust and Debris

Small wire brushes excel at removing rust and debris from various surfaces. Their bristles are designed to reach into crevices where dirt and corrosion tend to accumulate. This effectiveness makes them a popular choice for restoring metal items like tools and outdoor furniture. Users often find that the right pressure produces better results. However, too much pressure can damage the surface being cleaned.

Rust removal requires patience and precision. Small wire brushes can leave behind fine particles if not used correctly. Cleaning the brush after each use can improve its lifespan and effectiveness. Sometimes you'll notice stubborn rust that requires a more aggressive approach. In such cases, it might be worth considering other cleaning methods in tandem.

Debris, such as paint or grease, can also be effectively tackled with these brushes. Different bristle types can work better on specific materials. For example, stiff bristles may scratch softer metals. This unpredictability highlights the importance of selecting the right brush for your task. Ultimately, while small wire brushes are effective, careful consideration is needed for optimal cleaning results.

Maintenance Tips for Prolonging the Life of Wire Brushes

Maintaining small wire brushes is crucial for effective cleaning and longevity. These tools can wear down quickly if not properly cared for. Regular maintenance can extend their lifespan significantly. According to a study by the Industrial Wire Brush Association, proper care can increase the useful life by up to 50%. This means better value for your investment.

Tip: After each use, clean the bristles with compressed air. This removes debris and prevents buildup that can damage the wires. Avoid soaking brushes in water, as this can lead to rust. Instead, wipe them down with a dry cloth.

Another maintenance tip involves proper storage. Store wire brushes in a dry place. Humidity causes rust, which can render the brush ineffective. Observational data suggest that brushes stored in optimal conditions can last twice as long. Using a protective cover or casing can further prevent wear and tear.

In summary, a little care can go a long way. Regular inspections help catch issues early. Reflections on your cleaning habits may reveal common mistakes, such as neglecting brush care. By changing how you maintain your wire brushes, you ensure better performance and efficiency.

Safety Considerations When Using Small Wire Brushes for Cleaning

When using small wire brushes for cleaning, safety is a critical concern. These brushes can generate fine metal particles and debris, which can cause injury if proper precautions are not taken. A report from the American National Standards Institute highlighted that nearly 35% of injuries occur due to improper handling of wire brushes. This statistic underscores the need for proper equipment and safety measures.

Wearing protective gear is essential. Safety goggles can prevent eye injuries from flying debris. Similarly, gloves can protect hands from cuts and scrapes. Inadequate protection has led to many preventable incidents. An estimated 20% of wire brush-related injuries involve the hands. Not using the right safety equipment can be a regrettable oversight.

In addition, choosing the correct wire brush for the job is vital. Using a brush with the wrong bristle type may result in ineffective cleaning and safety hazards. Reports indicate that improper tool selection results in 15% of user injuries. It's crucial to reflect on these choices before starting a task. Small wire brushes can be effective, yet they carry risks. Awareness and preparation can significantly enhance safety while cleaning.

Related Posts

-

Exploring the Impact of Wire Brush Innovations at the 2025 China Import and Export Fair

-

Top Uses for Wire Brushes: Essential Tips for Effective Cleaning and Maintenance

-

Top Wire Brush Types to Choose for Effective Cleaning in 2025

-

10 Essential Tips for Using a Wire Brush Effectively in Your Projects

-

Best Small Wire Brush Options for Cleaning and Maintenance in 2025

-

What is a Metal Mesh Screen and How is it Used in Different Applications