What is Safety Wire and How is it Used in Engineering?

In the engineering world, safety wire plays a crucial role in ensuring the reliability of critical components. John Smith, a renowned safety wire expert, emphasizes its importance by stating, "Safety wire is essential for preventing loosening in high-stress environments." This highlights how safety wire acts as a safeguard in various applications, from aerospace to automotive.

The design of safety wire might seem simple. However, its effectiveness is essential. Using it improperly can lead to catastrophic failures. Engineers must choose the right materials and techniques. Each application presents unique challenges that require careful thought. Overlooking these details can have serious consequences.

Safety wire is not just a technical necessity; it’s a matter of trust. Engineers depend on it to ensure the safety and functionality of their designs. Understanding its role and the potential pitfalls is vital. As manufacturing processes evolve, so must our approach to safety wire practices. Continuous reflection on its use can lead to improvements in safety and efficiency.

What is Safety Wire? Definition and Overview

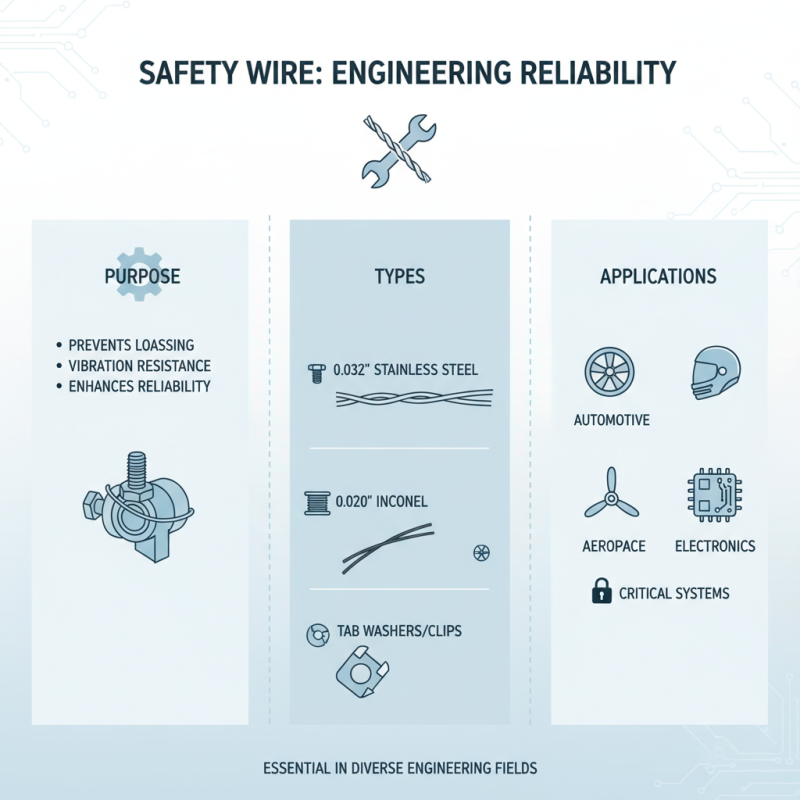

Safety wire is a crucial component in engineering, ensuring the integrity of machinery and equipment. It prevents critical components from loosening or detaching during operation. This is especially important in high-vibration environments, such as in aerospace or automotive applications. The wire is typically made from stainless steel or other durable materials, providing both strength and resistance to corrosion.

Using safety wire involves winding the wire around fasteners or bolts, creating a secure connection. This technique requires precision. The wire must be taut but not overly tight, which can cause stress on the components. Sometimes, individuals might rush this process, leading to improper tension. Such mistakes can compromise safety. Engaging in a thorough inspection before finalizing any assembly is essential.

It is worth noting that the practice of safety wiring is not just mechanical. It requires careful thought and attention to detail. There may be moments of uncertainty regarding the correct application methods and materials. These challenges reflect the complexities inherent in engineering tasks. Recognizing these hurdles can improve overall safety practices and enhance the reliability of engineering projects.

What is Safety Wire and How is it Used in Engineering? - What is Safety Wire? Definition and Overview

| Dimension | Description | Applications | Material Types | Installation Method |

|---|---|---|---|---|

| Diameter | The thickness of the wire, affecting its strength and flexibility | Aerospace, automotive, industrial machinery | Stainless steel, titanium, copper alloy | Twisting around fasteners or components |

| Strength | The load-bearing capacity of the wire | Preventing loosening in high-vibration environments | High-strength alloys, carbon steel | Using specialized safety wire tools |

| Length | The length of the wire used for safety applications | Mechanical assemblies, equipment maintenance | Galvanized steel, aircraft-grade wire | Looping and securing methods |

| Twist Ratio | The number of twists per inch of wire | Used in safety-critical applications | Plastic-coated wire, insulated varieties | Following manufacturer specifications |

History of Safety Wire Use in Engineering

Safety wire has a long history in engineering. It was initially adopted in the aviation industry. Engineers needed a reliable way to secure components in high-stress environments.

Safety wire provides a simple yet effective solution. It prevents bolts and nuts from loosening over time.

The use of safety wire dates back to World War II. Pilots needed to ensure their aircraft assembly was secure. The high stakes of aerial combat demanded unwavering reliability.

Safety wire quickly became a standard in military and commercial aviation. Its effectiveness caught on in automotive and other engineering sectors as well.

Despite its success, mistakes still occur with safety wire. Some engineers overlook proper tension. Others might forget to follow standard practices.

These oversights can compromise safety and lead to failures. Continued education and training are crucial. The ongoing challenge is to maintain

high safety standards in all applications.

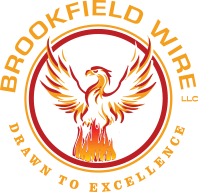

Types of Safety Wire and Their Applications

Safety wire is essential in various engineering fields to enhance reliability. It prevents components from loosening under vibration. Different types of safety wire serve unique purposes based on their applications.

There are two main types: single wire and twisted wire. Single wire is simple and effective for minor assemblies. Twisted wire provides additional strength. It is often used in aviation and motor sports to secure critical parts. The choice between these types depends on the application and the potential for movement.

Tips: Always choose the right gauge for your project. A thicker wire is stronger but harder to work with. Practice twisting techniques to ensure a secure bond. Mistakes can happen; check your work consistently to avoid failure in the field. Too loose or too tight can lead to issues. A good fit is key.

Mechanical Properties and Standards of Safety Wire

Safety wire is critical in engineering applications, particularly in aerospace and automotive sectors. It prevents fasteners from loosening due to vibrations. The mechanical properties of safety wire vary based on material. Common choices include stainless steel and monel. These materials provide excellent tensile strength and corrosion resistance.

According to industry standards, safety wire typically ranges from 0.020 to 0.041 inches in diameter. The tensile strength often exceeds 200,000 psi. This strength ensures that the wire can withstand significant loads without failing. Additionally, various standards dictate how safety wire should be installed. Proper installation techniques include twisting the wire to ensure a secure fit.

Tips: Always check the wire for any signs of wear before use. Documentation of installation procedures is also beneficial. Look for certification on safety wire to ensure compliance with industry standards. Regular audits can help identify recurring issues. Re-evaluate your processes if you find frequent failures. Staying updated with the latest standards can enhance safety and reliability.

Best Practices for Installing Safety Wire in Engineering Projects

Safety wire is essential in engineering for securing critical components. Proper installation ensures they remain tightly fastened during operation. Here are some best practices to follow for effective safety wire installation.

When installing safety wire, use the appropriate gauge for your application. A slightly thicker wire can provide more resilience. Wrap the wire tightly around the fasteners. This prevents any loosening due to vibrations. Make sure to twist the wire securely, with about five to six turns recommended.

**Tips:** Always clean the surfaces before installation. Dirt can reduce the wire's effectiveness. After installation, double-check your work to ensure everything is secure. A loose wire defeats the purpose and may lead to failure.

Don't rush the process. Take your time to ensure proper tension. If it feels off, it probably is. Remind yourself to reflect on each step. Safety is paramount in engineering projects, and mistakes can be costly. Regular training can help reduce errors in installations.

Related Posts

-

Top Uses for Wire Brushes: Essential Tips for Effective Cleaning and Maintenance

-

Top 10 Applications and Benefits of Steel Wire You Need to Know!

-

Discovering the Versatility and Durability of 304 Stainless Steel in Modern Applications

-

Revitalize Your Cleaning Routine: Discover the Power of Steel Brushes for Every Task

-

Mastering Stainless Steel Welding Techniques for Superior Joints and Durability

-

What is a Stainless Steel Supplier and How to Choose the Right One