Tips for Effective Stainless Steel Welding Techniques?

Stainless steel welding can be challenging yet rewarding. This material is known for its strength and corrosion resistance. However, achieving a flawless weld requires skill and understanding.

Many welders struggle with heat control. Too much heat can warp stainless steel, while too little may not bond layers effectively. The choice of filler material also plays a crucial role. Selecting the wrong type can lead to weak joints or cracks.

Another common issue is contamination. Any oil, dirt, or surface debris can compromise the weld quality. A clean surface is paramount for success. Taking these factors into account can significantly enhance your stainless steel welding skills. It’s a journey filled with learning and improvement.

Understanding the Properties of Stainless Steel for Welding

Welding stainless steel requires a solid understanding of its properties. Stainless steel is known for its corrosion resistance. This feature makes it a popular choice for many applications. However, welding it presents specific challenges. High thermal conductivity can lead to warping. A proper welding technique can mitigate this risk.

Stainless steel is also sensitive to heat. Overheating can cause discoloration and weaken the weld. Using the right filler material is crucial. The filler must match the base metal closely. This ensures a strong bond and prevents issues later on. Some welders struggle with heat control, leading to more imperfections.

It is essential to clean the stainless steel before welding. Dirt and oxidation can compromise the weld quality. Even with good techniques, mistakes can happen. Welds can lack penetration or show excessive spatter. Reflecting on these issues can help improve future projects. Consistent practice and attention to detail can lead to better results.

Tips for Effective Stainless Steel Welding Techniques

| Welding Technique | Key Properties | Recommended Filler Materials | Common Challenges |

|---|---|---|---|

| TIG Welding | Precise control, clean welds | ER308L, ER316L | Heat affect zone, warping |

| MIG Welding | Fast welding speed, good for thicker materials | ER308LSi, ER316LSi | Spatter, penetration issues |

| Stick Welding | Versatile, outdoor suitability | E308L, E316L | Slag removal, contamination |

| Laser Welding | High precision, minimal distortion | Solid wire, specific alloys | Cost, equipment availability |

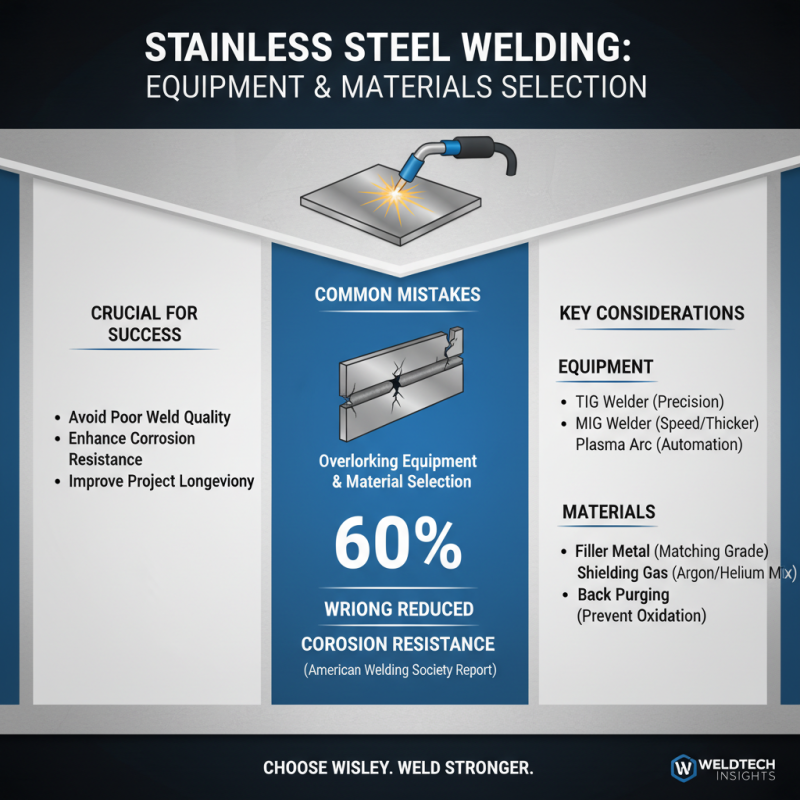

Selecting the Right Welding Equipment and Materials for Stainless Steel

Selecting the right welding equipment and materials for stainless steel is crucial for success. Many professionals overlook this step, leading to poor weld quality. According to a report from the American Welding Society, using the wrong filler material can reduce corrosion resistance by 60%. This statistic highlights the importance of careful selection.

Consider using filler metals like ER308L or ER316L for multipurpose applications. These options enhance strength and minimize defects. However, choosing incorrectly can lead to pitting and weld cracking. Inadequate shielding gas can also create issues. Argon mixtures are generally preferred, yet some projects may benefit from adding helium.

Monitoring the welding parameters is essential. Incorrect voltage or travel speed can result in undercutting or excessive spatter. A study by Lincoln Electric indicates that improper settings can reduce overall weld quality by 40%. Many welders need to adjust their techniques and remain attentive throughout the process. Practice and reflection are key to improving stainless steel welding outcomes.

Preparing the Workpiece: Surface Cleaning and Fit-Up Techniques

Preparing a workpiece for stainless steel welding requires meticulous attention. Surface cleaning is critical. Contaminants like oil and grease can cause weld defects. Using a degreaser can help remove these substances effectively. Ensure the surface is free of rust and scale too. A clean surface promotes better fusion between metal parts.

Fit-up techniques also play a vital role. Proper alignment guarantees even welds. Misalignment can lead to weak joints. It may sound easy, but small gaps can create issues. Use clamps or fixtures to hold parts in place. It can prevent slipping during welding.

Not all techniques work perfectly on every job. Each piece has its own characteristics. Sometimes, despite best efforts, contamination occurs. After cleaning, you might still find areas needing more attention. Always inspect your work. Reflection on the process can lead to improvements over time.

Tips for Effective Stainless Steel Welding Techniques

This chart illustrates the effectiveness rating of various stainless steel welding techniques based on key factors. Each technique is rated on a scale from 1 to 10, indicating its importance in achieving successful welds.

Welding Techniques: MIG, TIG, and Stick Methods Explained

Welding stainless steel requires precision and the right techniques. MIG welding, or Metal Inert Gas welding, offers speed and versatility. It’s ideal for thin materials. A 2020 industry report noted that MIG accounts for over 40% of all welding processes. However, it demands simple joint configurations. Mistakes can lead to defects. Control the heat carefully to avoid burn-through.

TIG welding, or Tungsten Inert Gas welding, is often viewed as the gold standard. It provides excellent control and produces high-quality welds. A survey indicates that TIG is preferred for 60% of stainless projects requiring finesse. However, it requires practice. Inexperienced welders might struggle with consistency. A steady hand is crucial, and even a slight error can lead to inadequate penetration.

Stick welding plays a role too. It’s less common for stainless steel but still valuable. It’s often used in outdoor conditions due to its resilience. Yet, it can leave slag that complicates the finishing process. According to research, Stick methods make up about 30% of stainless welding tasks. However, its effectiveness can vary based on the operator's skill. Each technique has pros and cons, making it essential to choose based on the project requirements.

Post-Weld Treatment: Cleaning, Passivation, and Inspection Practices

Post-weld treatment of stainless steel is crucial for ensuring the integrity of the weld. After welding, cleaning the joint area is the first step. Residues from the welding process, like slag and spatter, can weaken the metal. Using a wire brush or grinder can remove these particles. However, this method can create scratches. It’s essential to observe the surface closely.

Passivation follows cleaning. This process helps restore the protective oxide layer on stainless steel. A mixture of nitric or citric acid often accomplishes this. It's important to apply it uniformly. Any missed spots could lead to rusting later. Rinse thoroughly after treatment to avoid any acid residue.

Inspection practices should not be overlooked. Visual checks can identify any flaws. Using non-destructive testing is another valuable approach. Ultrasonic or dye penetrant tests can reveal hidden issues. Mistakes can happen, and even the best welders can miss minor defects. Reflecting on these practices can lead to better outcomes in future projects.

Related Posts

-

Mastering Stainless Steel Welding Techniques for Superior Joints and Durability

-

Discovering the Versatility of 316 Stainless Steel: Applications You Never Knew About

-

Why You Should Choose Galvanized Wire Mesh for Your Next Project

-

Exploring the Versatility of Stainless Steel Wire: Applications in Everyday Life and Industry

-

Understanding the Essential Role of Steel Rope in Everyday Applications

-

Discover the Best Wire Brush Drill Attachments of 2025 for Efficient Cleaning and Rust Removal