How to Choose the Right Steel Wire Rope for Your Project?

When it comes to construction projects, choosing the right steel wire rope is crucial. Renowned industry expert John Smith emphasizes, "The right steel wire rope can make or break your project." The correct selection impacts safety, efficiency, and longevity.

Steel wire ropes come in various configurations, sizes, and materials. Understanding your specific needs is vital. Not all ropes are created equal. Some are designed for heavy lifting, while others suit different environmental conditions.

Many projects suffer from poor choice of materials. This can lead to unforeseen issues. Inspecting the steel wire rope carefully before use is essential. Experience tells us that overlooking this step can result in costly mistakes. Take time to understand the specifications. It could be the difference between success and failure.

Understanding the Different Types of Steel Wire Ropes Available

When selecting a steel wire rope, understanding the different types is crucial. Steel wire ropes come in various constructions, each designed for specific applications. The most common types include 6x19, 6x36, and 7x19 constructions. Each consists of strands made up of smaller wires, affecting flexibility, strength, and wear resistance.

Tips for choosing the right type: Evaluate your project's load requirements. Higher load capacities often require a thicker rope with more strands. Consider the environment. Saltwater and chemicals can corrode some materials.

The right choice impacts both performance and safety. Inspect available ropes carefully. Look for signs of wear or damage. A rope's lifespan can vary based on usage. A heavy load might mean more frequent replacements.

Occasionally, you may need to compromise. A rope that’s too stiff can hinder movement. Meanwhile, a very flexible rope may struggle under heavy loads. Finding the balance is key. Always seek advice if unsure. Proper selection ensures your project's success.

How to Choose the Right Steel Wire Rope for Your Project?

| Type of Steel Wire Rope | Construction | Diameter (mm) | Strength (kN) | Common Uses |

|---|---|---|---|---|

| 6x19 | 6 strands of 19 wires | 8 | 60 | General lifting purposes |

| 7x7 | 7 strands of 7 wires | 10 | 85 | Lifting equipment, cranes |

| 8x19 | 8 strands of 19 wires | 12 | 110 | Mining, construction |

| 19x7 | 19 strands of 7 wires | 14 | 125 | Heavy lifting, towing |

| 6x36 | 6 strands of 36 wires | 16 | 150 | Marine applications, winches |

Assessing Load Requirements for Your Specific Project Needs

When assessing load requirements for your project, clarity is crucial. Begin by determining the maximum load your steel wire rope will bear. This includes the weight of the items and any additional forces applied during use. Consider dynamic loads too. These can cause spikes in tension, affecting the rope’s performance.

Next, think about the environment. Will the rope be exposed to chemicals or extreme temperatures? Such factors influence the choice of material. A durable coating may be necessary to enhance resistance. Pay attention to the rope's diameter and construction type. Thicker ropes often handle more weight but may not fit your project’s specific constraints.

Reflect on potential safety margins. It’s easy to underestimate the load, leading to dangerous situations. Always opt for a higher capacity than you think you'll need. This oversight can have lasting consequences. Measure carefully and consult various sources to ensure you make informed decisions. Each project is unique; don’t treat them all the same.

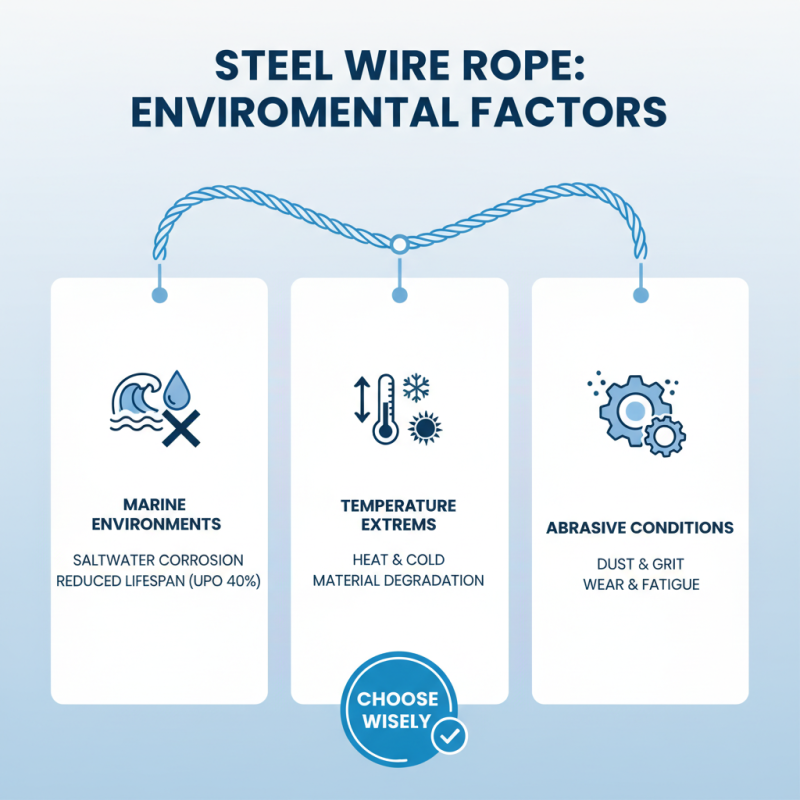

Evaluating Environmental Factors Affecting Wire Rope Selection

When choosing steel wire rope, environmental factors play a crucial role. The conditions where the rope will be used greatly impact its longevity and performance. For instance, ropes used in marine environments face saltwater corrosion. A report from the Wire Rope Technical Board indicates that such exposure can reduce the lifespan of steel wire rope by up to 40%. This factor alone must be addressed when making a selection.

Temperature variations are another critical consideration. Extreme heat can weaken the wire. In contrast, very low temperatures can make it brittle. According to the American Society of Mechanical Engineers, steel’s tensile strength can decrease by about 20% at temperatures below -20°F. These insights highlight the need to evaluate the specific climate conditions of your project.

Additional elements include chemical exposure and physical abrasion. Ropes used in construction might encounter concrete dust. This can wear down the strands over time. Surprisingly, some users overlook these aspects. They assume that all steel wire ropes will perform the same. However, not noting these details can lead to unanticipated failures and costly downtime. Always assess your environment thoroughly before making a final decision.

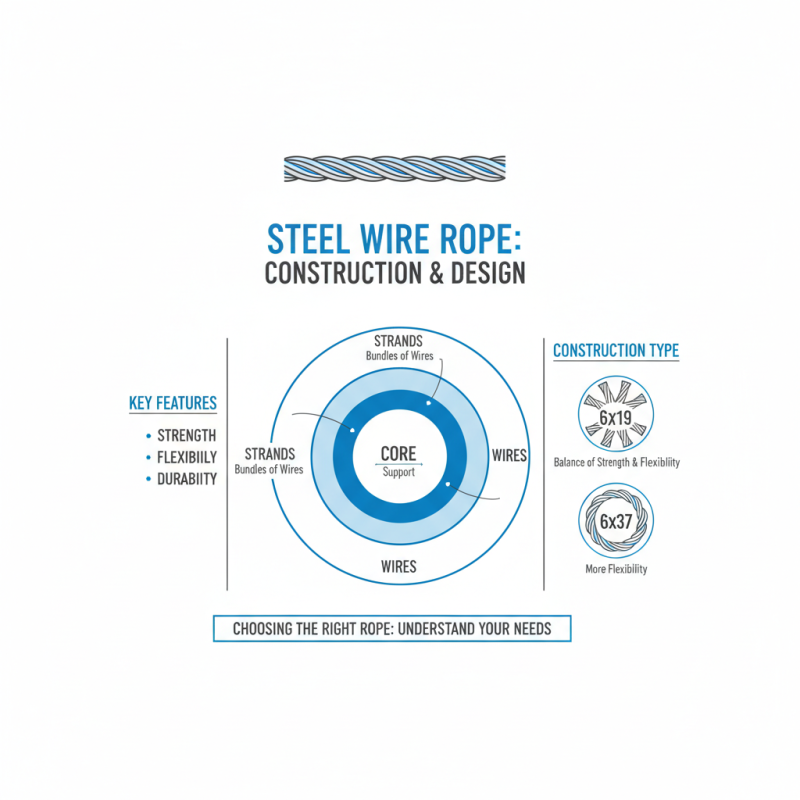

Examining Wire Rope Construction and Design Features

Choosing the right steel wire rope involves understanding its construction and design features. Steel wire ropes are made up of multiple strands, which contain individual wires. The arrangement and number of these strands significantly impact the rope's strength and flexibility. For instance, a 6x19 construction offers a good balance of flexibility and strength, making it popular in various applications.

When evaluating wire rope for your project, consider aspects like lay direction and wire diameter. Right lay and left lay configurations have different torsional characteristics. Also, thicker wires usually yield higher strength. According to industry reports, selecting a wire rope with a diameter increase of just 10% can enhance the load capacity by approximately 20%. This trade-off between flexibility and strength is crucial.

**Tip:** Always match the wire rope to your specific project requirements. Check the load ratings and consider environmental factors like abrasion and corrosion.

In some cases, users overlook maintenance needs. Regular inspections can catch issues before they escalate. Remember, a wire rope may look intact but harbor internal damage. This is a common oversight that can lead to safety hazards.

**Tip:** Establish an inspection schedule. Frequent checks can extend the life of your wire rope and ensure safe operation.

Considering Maintenance and Durability for Long-Term Use

When choosing the right steel wire rope, maintenance and durability play crucial roles in long-term use. The selection process often seems straightforward, yet many overlook vital factors. For example, corrosion resistance is essential if the rope will be exposed to harsh environments. Some might choose based solely on strength, forgetting that even the strongest rope can fail without proper upkeep.

Regular inspections are crucial. Worn spots or fraying can signal potential failure. It's easy to assume everything is fine, but neglecting these details could lead to costly accidents. Additionally, understanding the rope's application environment helps. A rope used underwater requires different care than one used in construction.

Durability is not just about the initial choice. Different coatings can enhance resistance to wear and tear. However, applying these coatings requires attention and care. Environmental impacts also affect lifespan. Exposure to extreme temperatures can weaken even the best materials. Reflecting on these details can lead to better decisions that ensure safety and longevity.

Comparison of Steel Wire Rope Types Based on Durability and Maintenance Factors

Related Posts

-

Understanding the Essential Role of Steel Rope in Everyday Applications

-

7 Best Practices for Choosing the Right Steel Wire for Your Projects

-

2025 Top 5 Stainless Steel Wire Rope Trends You Need to Know

-

Top 10 Stainless Steel Supplier Factors Influencing Market Growth and Demand in 2023

-

Top Uses for Wire Brushes: Essential Tips for Effective Cleaning and Maintenance

-

Discover the Best Wire Brush Drill Attachments of 2025 for Efficient Cleaning and Rust Removal