What is a Brass Wire Brush and How is it Used?

A brass wire brush is a versatile tool commonly used in various applications. It features bristles made from brass, a metal known for its durability and corrosion resistance. This brush effectively removes rust, paint, and grime from surfaces, making it essential for maintenance tasks.

Using a brass wire brush can be straightforward, yet it requires some technique. When cleaning delicate materials, users should apply gentle pressure. Too much force may damage the surface. Additionally, the brush can scratch softer metals or coatings if not handled carefully.

It's important to choose the right brush size and bristle stiffness for the job. Using the wrong type can lead to poor results and frustration. Reflecting on the technique can enhance effectiveness. A brass wire brush is a valuable tool, yet it demands respect and care to be truly effective.

What is a Brass Wire Brush?

A brass wire brush is a tool used primarily for cleaning and deburring metal surfaces. Its bristles are made from brass, a softer metal than steel, which makes it suitable for gentle cleaning. This brush effectively removes rust, grime, and paint without damaging the underlying material. It is a favorite among hobbyists and professionals in metalwork and woodworking.

When using a brass wire brush, grip it firmly and apply consistent pressure. Maintain a steady motion across the surface to ensure even cleaning. Avoid pressing too hard, as this can lead to bristle wear or surface scratches. Remember, not every brush stroke will be perfect. Occasionally, you might miss spots or apply uneven pressure. Reflecting on your technique can help improve future uses.

**Tips:** Always wear safety goggles when using a wire brush. This protects your eyes from flying debris. Clean the brush regularly to maintain its effectiveness. After use, store it in a dry place to prevent rust on the bristles.

Components and Construction of a Brass Wire Brush

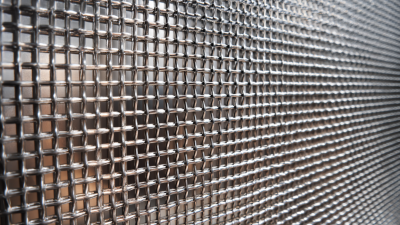

A brass wire brush consists of bristles made from brass wires. These wires are typically twisted together to form a robust brush head. The brass material prevents rust, making it suitable for cleaning metal surfaces. The handle is often made of wood or plastic for a comfortable grip.

When using a brass wire brush, it’s essential to apply the right amount of pressure. Too much pressure can damage the surface being cleaned. The ideal technique involves moving the brush in a consistent motion. This helps remove debris without causing scratches.

Every brush has its limits. Over time, the bristles may wear out, requiring replacement. Regular inspection of the brush ensures optimal performance. It’s easy to overlook this detail, but maintaining your tools matters. Reflection on this can lead to better cleaning results.

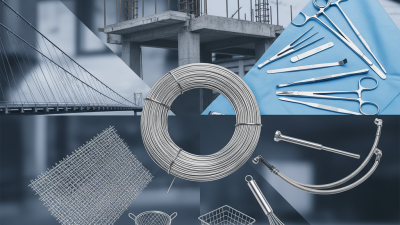

Applications of Brass Wire Brushes in Various Industries

Brass wire brushes are versatile tools used in various industries for cleaning and finishing. These brushes are known for their ability to remove rust, paint, and other contaminants from surfaces. Their soft bristles protect the base material while effectively cleaning it.

In the automotive industry, brass wire brushes are frequently employed for engine cleaning and maintenance. A study by the Automotive Maintenance Association indicates that using these brushes can reduce cleaning time by up to 30%. This efficiency helps mechanics spend more time on repairs rather than cleaning.

The electronics sector also benefits from brass wire brushes. They are used to prepare surfaces for soldering, ensuring strong and reliable connections. According to a report by the Electronics Manufacturing Institute, improper surface preparation can lead to a 15% increase in defect rates. Effective brushing addresses this issue but not all companies have adopted this practice. Some still overlook the importance of using the right type of brush for specific tasks.

How to Properly Use a Brass Wire Brush

Using a brass wire brush effectively requires attention and care. These brushes are ideal for cleaning and prepping metal surfaces. They excel at removing rust, paint, and dirt. When using a brass wire brush, it's important to hold it at a consistent angle. This ensures a more even distribution of pressure. The goal is to clean without scratching the metal underneath.

Before you start, make sure to wear protective gear. Safety goggles and gloves are crucial. They protect against flying debris. Start with light pressure. Too much force can damage the bristles. Move the brush in a straight line or circular motion. This can help you cover more area efficiently. If the bristles start to bend, it may be time for a replacement. Regularly check the brush for wear.

After using the brush, inspect the metal surface. Look for any imperfections or leftover debris. Sometimes, a second pass may be necessary. Using the brass wire brush takes practice. Reflect on your technique and adjust as needed. Each project offers a learning opportunity. Embrace the process and become more adept with each use.

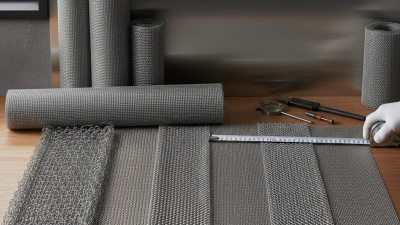

Maintenance and Care for Brass Wire Brushes

Brass wire brushes are essential tools in many industries. They are widely used for cleaning metal surfaces, removing rust, and preparing surfaces for painting. Proper maintenance of these brushes is crucial to ensure their longevity and effectiveness. Regular inspection can help identify bristle wear or deformation, which may impair performance.

To maintain a brass wire brush, users should clean it after each use. Simply rinsing off the debris and contaminants can extend the brush's life. According to industry reports, brushes that are properly maintained can last up to 50% longer than those that are neglected. Storing brushes in a dry place is equally important. Exposure to moisture can lead to corrosion, compromising the bristles.

While users often overlook the care of these brushes, it’s vital to reflect on their maintenance habits. Neglected brushes can result in poor cleaning performance. Additionally, a worn brush can cause scratches on delicate surfaces. Regular care may seem tedious but can significantly enhance the tool’s efficiency and durability in the long run.

Usage Frequency of Brass Wire Brushes in Various Applications

Related Posts

-

Why Stainless Steel Mesh Screens Are Essential for Your Home and Industry Needs

-

The Ultimate Guide to Choosing the Best Tie Wire for Construction Projects

-

2026 How to Choose the Best Stainless Steel Screen for Your Needs?

-

Top 10 Uses of Stainless Steel Wire in Everyday Applications

-

Understanding the Essential Role of Steel Rope in Everyday Applications

-

2025 How to Choose the Best Stainless Steel Mesh Screen for Your Needs