2026 Top Stainless Steel Supplier Trends and Insights?

In recent years, the role of a stainless steel supplier has evolved significantly. The landscape is changing rapidly, driven by market demands and technological advancements. As John Doe, a leading expert in the stainless steel industry, once stated, "Understanding the industry's trends is crucial for any successful stainless steel supplier." This insight highlights the importance of staying ahead in a competitive market.

The current trends reveal a growing focus on sustainability and innovative production methods. Many suppliers now prioritize eco-friendly practices. This shift not only meets regulatory requirements but also aligns with consumer expectations. Suppliers must adapt to these changes, or risk falling behind.

However, challenges remain. Some suppliers struggle to balance cost-effectiveness with quality. Others face difficulties in managing supply chain disruptions. As the industry evolves, reflection and adaptation are vital. Suppliers need to navigate these complexities to thrive in 2026 and beyond. Staying informed and flexible will be key to success in this dynamic environment.

Emerging Technologies in Stainless Steel Manufacturing for 2026

In 2026, stainless steel manufacturing is on the brink of transformation. Emerging technologies are redefining production processes. Advanced robotics will play a crucial role. These machines can operate with precision and efficiency. They help reduce waste and improve safety on factory floors.

Additive manufacturing is gaining traction too. This technology allows for creating complex shapes that traditional methods can’t. It reduces the need for extensive machining, conserving material. Moreover, using AI in quality control enhances product reliability. Factories can spot defects early, minimizing costly reworks.

However, these advancements bring challenges. Not all manufacturers can afford cutting-edge equipment. Skills gaps in the workforce pose hurdles. Companies may struggle to integrate new technologies seamlessly. As the industry evolves, these issues need addressing. Embracing change is vital, but it requires thoughtful planning and investment. It's a journey filled with opportunities and obstacles alike.

Sustainability Practices Impacting the Stainless Steel Supply Chain

Sustainability practices are reshaping the stainless steel supply chain. Companies increasingly focus on reducing their carbon footprint. This shift is driven by both consumer demand and regulatory pressures. Many industries now prioritize eco-friendly materials. Stainless steel, known for its durability and recyclability, stands out.

Recycling processes are becoming more effective. Recovery rates for stainless scrap have improved significantly. Yet, not all suppliers are aligned with these practices. Some still rely on traditional methods that are less sustainable. This inconsistency creates challenges within the supply chain.

Transparency is crucial. Consumers want to know where their products come from. A lack of clarity can lead to mistrust. Suppliers must adopt clearer policies regarding their sourcing and production methods. As these sustainability trends continue, reflection on past practices is necessary. We must question our commitment to a greener future. Recognizing flaws will help the industry progress.

Market Demand Shifts: Key Industries Driving Stainless Steel Trends

The stainless steel market is experiencing significant shifts. Key industries are driving changes in demand and supply dynamics. Construction, automotive, and consumer goods are the front runners in this transformation.

In the construction sector, sustainable building practices are gaining traction. More projects prioritize eco-friendly materials. This shift pushes stainless steel into the spotlight. Its durability and recyclability meet modern requirements. However, the industry faces challenges. Fluctuating raw material prices can complicate planning. There is room for improvement in forecasting these changes.

The automotive industry is increasingly adopting stainless steel for its strength and aesthetic appeal. Electric vehicles, in particular, demand lightweight and strong materials. This trend places a focus on innovative alloys. Yet, manufacturers must address the recycling of older materials. Finding a balance between innovation and sustainability is essential.

2026 Top Stainless Steel Supplier Trends and Insights

Global Trade Dynamics Affecting Stainless Steel Suppliers in 2026

The global trade dynamics are shifting rapidly, impacting stainless steel suppliers significantly. In 2026, the demand for stainless steel is projected to increase by approximately 5% annually. This demand surge is primarily driven by growth in the construction and automotive sectors. However, trade policies and tariffs continue to create hurdles for suppliers.

In recent reports, the World Steel Association highlighted that the trade conflicts may lead to fluctuating prices. For instance, raw material costs are expected to rise by 4-6%, affecting profit margins. Additionally, logistics challenges continue to plague the industry. The ongoing demand for sustainability complicates supply chains further. Suppliers must adapt to changing regulations and consumer expectations regarding eco-friendly practices.

Competitors in the stainless steel market must be agile. With supply chain disruptions, steelmakers may struggle to meet delivery timelines. Companies should invest in technology to enhance efficiency. Keeping an eye on global trade agreements is crucial. Ignoring these trends could result in missed opportunities. As the industry evolves, suppliers need to continuously reassess their strategies.

2026 Top Stainless Steel Supplier Trends and Insights

| Trend | Insight | Percentage Impact | Region | Projected Growth Rate |

|---|---|---|---|---|

| Increased Demand for Sustainable Products | Consumers are favoring eco-friendly options, pushing suppliers to adapt. | 25% | North America | 5% |

| Technological Advancements | Automation and AI are streamlining production processes. | 30% | Europe | 7% |

| Supply Chain Sustainability | Suppliers are focusing on reducing carbon footprints throughout the supply chain. | 20% | Asia Pacific | 6% |

| Market Diversification | Companies are entering new markets to mitigate risks associated with economic fluctuations. | 15% | Latin America | 4% |

| E-commerce and Digitalization | Online sales platforms are gaining traction in the stainless steel market. | 35% | Global | 10% |

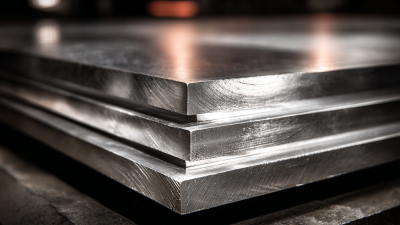

Innovations in Stainless Steel Alloys and Their Industry Applications

The stainless steel industry is witnessing significant innovations in alloy development. Various advanced alloys are being introduced to enhance performance in different applications. For instance, the global market for stainless steel is projected to reach over $150 billion by 2026, according to industry reports. This growth is driven by the increasing demand from sectors like construction, automotive, and food processing.

Recently, new stainless steel alloys have demonstrated improved corrosion resistance and strength. Alloys like 316L and duplex stainless steels are gaining traction. They are ideal for marine and chemical processing environments. Industries are beginning to favor these materials due to their longevity and lower maintenance costs. In fact, studies show a 40% decrease in failure rates when switching to these advanced alloys.

However, challenges remain. Some manufacturers struggle with the cost of production. A balance between innovation and affordability is needed. Furthermore, sustainability concerns drive the urge for recycling and eco-friendly solutions. The industry must adapt to these demands to remain competitive. Innovations are crucial, but so is addressing economic and environmental factors.

Related Posts

-

The Ultimate Guide to Choosing the Right Stainless Steel Supplier for Your Projects

-

Top 10 Stainless Steel Supplier Factors Influencing Market Growth and Demand in 2023

-

What is a Stainless Steel Supplier and How to Choose the Right One

-

Discovering the Versatility and Durability of 304 Stainless Steel in Modern Applications

-

Why You Should Choose Galvanized Wire Mesh for Your Next Project

-

10 Essential Tips for Using a Wire Brush Effectively in Your Projects